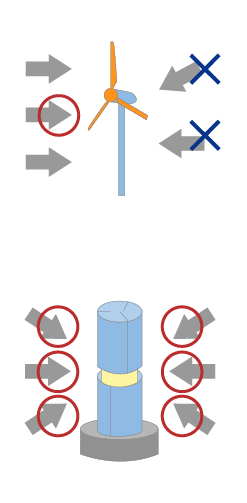

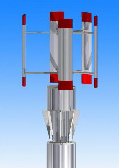

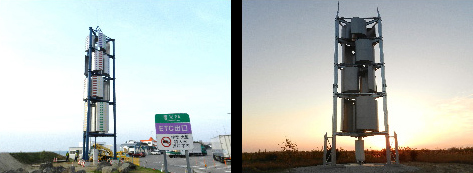

- The vertical design has a small installation footprint enabling multiple units to be installed in a small location.

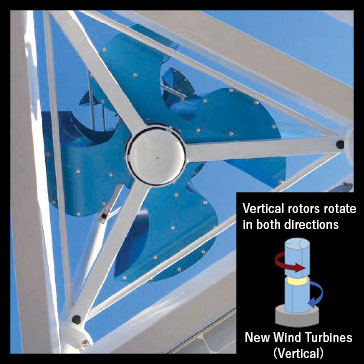

- The turbine accelerates to triple speed and blades invert rotation vertically neutralizing rotational torque.

- These turbines also equally support wind coming from any direction (360 degrees).

- This allows support for the characteristic Japanese wind that changes direction suddenly.

Conventional Wind Turbines

Propellor Turbines

The most popular style for wind power generation.

The three-bladed propeller turbine is most common.

high speeds. However, issues include noise, efficiency loss from neck oscillating movement and various maintenance related issues.

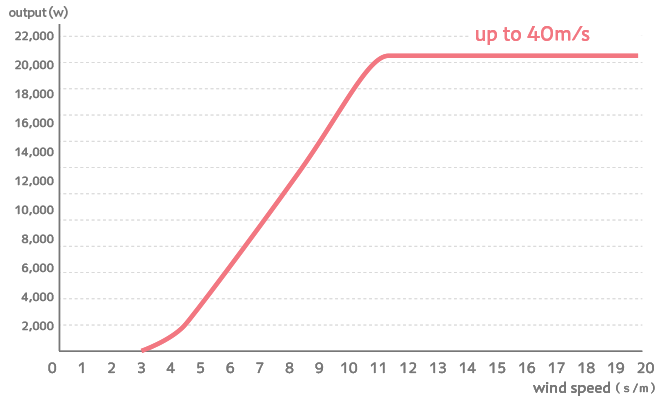

Furthermore, the so-called cut-in (power on) wind speed is high at 4 to 5m/s, they need to cut-out to prevent risks of over-spin in strong winds and a high cost of ownership from maintenance and management costs and the cost of the equipment.

Savonius Turbines

The turbine cylinder is cut in half vertically and are shifted in the periphery direction

Generally, resistance wind turbines are limited to use of between ten and twenty percent of the energy in wind.

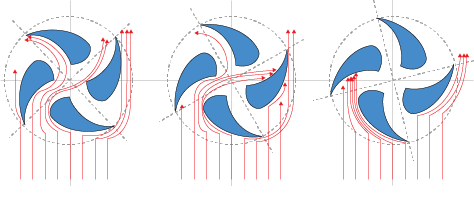

With a tip-speed ratio of under 1, these are quiet and generate large torque with good ability to start in even small amounts of wind. This model enables collection of wind from any direction without shaft oscillation.

Gyro-mill Turbines

These turbines have vertical blades with cross sections similar to airplane propeller blades.

Able to begin rotation on their own with high tip-speed ratio once rotation starts, these turbines have high rotating torque and have garnered a lot of attention.

Darrieus Turbines

These turbines have vertical blades with cross sections similar to airplane propeller blades bent into bow shapes mounted on a vertical shaft.

With an extremely low starting torque, it is unable to start rotating on its own and requires many innovations such as a starting motor or borrowing force from other turbines.

Characteristics of Tornado Wind Turbines

Small installation footprint

The vertical design gives it a small installation footprint enabling multiple units to be installed in a small location.

Since the cylindrical shape allows obtaining wind power from any direction, it may be installed without consideration of wind direction.

It can also be used to generate power in small locations.

Low noise

The design excels at silent operation that does not impede power generation efficiency.

Tornado wind turbines are the world’s first turbines to bring together the characteristics of Sarvonius wind turbines which excel at silent operation and gyro-mill wind turbines with their excellent rotation torque.

New blade shapes that excel at silent operation and rotation torque

With both lift and drag functionality, blades are combined in a quad stage vertical design so the turbine accelerates to triple speed and blades invert rotation vertically neutralizing rotational torque.

Bird safety

The design prevents bird strikes.

With excellent visibility, this design prevents accidents with birds better than conventional models (such as the common propeller type wind turbines).

Resistant to lightning strikes

The design prevent damage to motors from lightning strikes.

There are lightning rods on each of the three pillars of the triangular casing grounding inductive lightning strikes by each rod vertically minimizing damage.

The design of these lightning measures, the greatest threat to wind power generation, thoroughly minimizes risks of loss of the blades which are mounted with two shafts to the triangular case, even in the unfortunate case of direct lightning strike.

Triangular casing that minimizes damage

Designed so each of the three pillars has a lightning rod such that lightning is conducted to the ground without passing through the motor.

Propeller power generation broken by lightning strike

Resistant to gusts and typhoon strength winds

The three pillars and blades rotating in both directions make this design resistant to gusts and typhoon strength winds.

The design prevents damage including bending of pillars and even blades during high winds with the robust triangular frame.

The gyro effect of blades rotating in both directions increases the stability of the casing the faster they are spinning.

Instead of depending on mechanical force, the laws of nature are used to limit the impact characterizing this design as extremely durable to natural forces.

Experiment with a suspended tornado wind turbine

Even when taking the brunt of the occasional strong breeze, when the blades spin faster it stands vertically (gyro effect)

Once it begins turning it is difficult to stop (flywheel effect)

Since blades rotate in opposite directions, the casing (external frame) does not spin. (Neutralized reaction force)

Propeller power generation broken by gusts and typhoon strength winds

Low maintenance

A simple design with few malfunctions.

Since there is no pitch control or yaw movement, there are fewer parts making the design have fewer malfunctions than propeller wind turbines.

Low cost

No extra cost is needed.

Since it uses no power when still and there is no cut out, it is able to limit power generation costs.

As a drag type with low rotation and high torque, the rotation speed is not too high so it can be safely upscaled easily.

The mechanism is simple so it is possible to achieve upscaling with the same existing construction method while retaining low maintenance and malfunctions even when made large.

Consistent power generation efficiency

This design achieves stable operating rate without cutting out, achieving a good power generation rate.

With very low cut out, the tornado power turbine generating efficiency is able to generate during strong winds and allows a high operating rate compared to the worse performing propeller type. (In regions with strong winds, the annual power generation may vary greatly) Since this design can generate power through strong winds with lots of energy, ideal operation rates can be achieved.

Since wind is supported from all directions (360°), it is possible to supply a consistent amount of power generation.

Power Generation Characteristics of the 20kw Tornado Wind Turbine